Digitization of Manufacturing Industry is Bringing Optimized Results to the Table

In today’s article, we will be focusing on the challenges that the machine manufacturing industry is facing and how we as a digital transformation consultant can help them future-proof their business with digitization for a better tomorrow.

5 Mins Read

5 Mins Read

Introduction

As per recent Deloitte projections based on the Oxford Economic Model (OEM), a decline in annual manufacturing GDP growth level for 2020–2021 is anticipated, with a forecast of -6.3% for 2020 and 3.5% for 2021.

COVID-19 has brought in the largest health and economic crisis in recent history. Companies across sectors were forced to take extraordinary measures to protect their people and maintain operations. While some firms struggled to keep the operations running with the sudden spike in demand, many firms willed to run their business even with the shortages of raw materials and workers. At this point, many industries adopted digitization to fight through COVID and support the operational procedures and their people. One of such industries is the Industrial Machine Manufacturing Industry. They not only digitized operational processes but benefited from the new adoption. We will talk about it in detail in our upcoming blog.

The question here arises is whether the technology of the ongoing Fourth Industrial Revolution aka Industry 4.0 helped the Manufacturing Industry in its effort and investment during the Pandemic?

The answer is yes. According to the research executed by the team of Stark Digital Media Services, the best digital transformation consultant, 83% of manufacturing leaders describe Industry 4.0 as “extremely or very important” for their firms during the Pandemic and 56% think that Industry 4.0 will have a “significant impact” in the next five years.

Still not convinced why you should adopt digitization?

Stay tuned and continue reading!

Why is the Manufacturing Industry Going Online? Will Digitization help the B2B Industry?

As a digital transformation solution provider, we understand that being in the business for decades, you might not want to transform your business digitally, but the market today is responding differently. Information and technology are enabling the manufacturing industry to make data-driven decisions to increase their return on investment and sales rate with big data analysis, integrated systems, and technology-assisted processes brought in by a successful digital transformation.

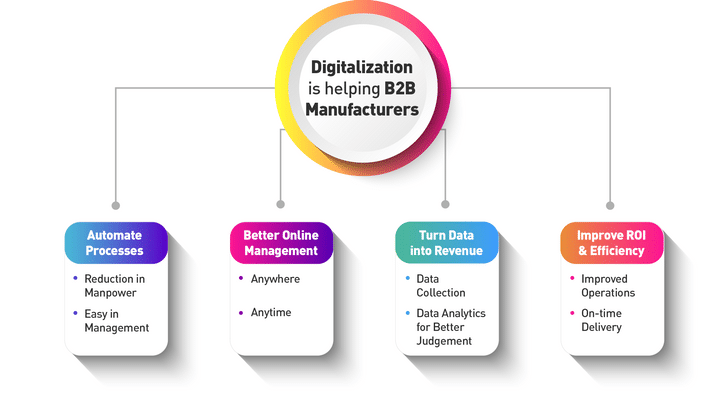

Machine Manufacturing Industry can benefit from digitizing its processes in numerous ways including:-

Automated Processes

Automated procedures integrate all the systems around the factories, enabling you to assess the working of the systems. It extensively reduces the requirement of manpower, allowing personnel to focus on essential brainstorming and management prerequisites.

Online Management

Easy online management of inventory, supply chain, system fault detection, human resource, and factory data ensures reduction in the turnaround time and on-time delivery of projects to the clients.

Turn Data into Revenue

By storing all the big data in one place, you ensure easy data analytics for unforeseen mishaps, allowing reduction of downtime, on-time machinery service and management, understanding the market better, and offering timely service to the client.

Improved ROI & Efficiency

With automated operations and streamlined procedures, get a better return on investment and improve your firm’s efficiency by threefold.

While digital transformation can facilitate a spectrum of advantages, it can also pose a lot of challenges during the transitional period. Due to which a trustworthy digital partner is advised when you are transitioning from your traditional methods of manufacturing to a digital one. Let’s see what are the challenges you face and the possible solutions we offer to the Manufacturing Industry.

Transitioning Challenges & Solutions

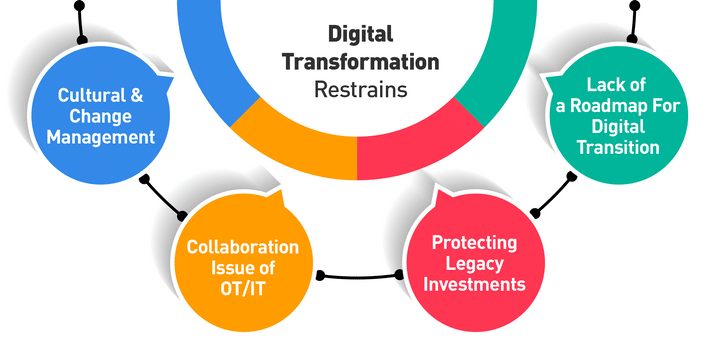

The Manufacturing Industry has been striving hard to transform digitally, however, the cultural and change management issues have been forcing the transition down the drain. As a best consulting firms for digital transformation we found out Some of the common restraints that the industry is facing today are shown in the image below.

Stark Digital Media Services Facilitates Effective Solutions

As your digital transformation consultant, we understand your firm’s challenges and so we have brought out some possible solutions for the same.

Align Digital Strategy with Corporate Strategy

Many manufacturing organizations take digital transformation strategy as a one-time thing that requires minimal attention; however, the truth of the matter is that digital transformation only works when the business goals and vision are interlinked with your digital strategy.

We ensure a smooth digital transition to your business by seamlessly interlinking your business goals with your digital strategy, allowing your firm to experience operational excellence and data analytics.

Keep a Customer-centric Approach

Manufacturing firms require to maintain a mindset and culture that keeps customer value, needs, and requirements as their priority while strategizing for the firm’s digital transformation. It has been proved that the firms that run a customer-driven business can seamlessly earn revenues 1.4 times faster than other manufacturing firms. Hence, as a digital transformation solution provider, we help you scrutinize and align the IT/OT systems to fulfill the unmet needs of your customers,

Organize Data and Stable Technology Foundation

Before venturing into your company’s digital transition, it’s essential to set up a strong information and technology core. Without a stable and strong data foundation, one cannot ensure an easy data analysis on which the company depends to grow digitally. In the manufacturing industry, as a digital transformation consultant, we offer data solutions to ensure better storage, information analysis to further achieve your business goal and operational excellence.

Target to sell your products online with Secure Environment and Authentication

B2B manufacturers need to commence interacting with their customers online by selling their products in a secure and authenticated environment. Fulfilling the requirements of the B2B clients online isn’t simple, particularly with their demand for the customized checkout workflows, product personalization, pricing rules as per customization, and further complex functions running in the background.

As a digital supply chain consultant, we aid manufacturing firms in building a secure customer-centric website design for manufacturing companies and planning a seamless traceable and transparent digital supply chain for the comfort of the seller and the buyer.

Revamp Your Online Presence without Losing Data

A wrong perception that manufacturing firms have about revamping their website is that they will lose all their data. Our experienced developers can easily revamp your website. There’s no loss of information involved in revamping your website as per the customers’ needs now and then.

Target Potential Customers with 360 Digital Marketing

Digital marketing is an essential and last step towards the digital transformation of a manufacturing firm. Marketing your company on digital platforms to generate leads and connect with potential customers is imperative, but a daunting task for many.

A manufacturing firm’s challenges are finding a foothold amidst scarce skills, absence of digital readiness, and limited budget. Many firms fail to understand the complexities of digital marketing as a whole. We offer a fully integrated digital marketing plan for B2B manufacturing firms to leverage sales intelligence with marketing operations for high performance. Our cost-effective marketing strategy will ensure rapid advancement and opportunities to attract leads within no time.

Partner with us to create your Digital Tomorrow

The above digits and factors show a win for companies that had already upgraded digitally. A reality check for those who are in the process of scaling, and a wake-up call for those who haven’t started their journey of digital transformation.

Digital transformation, if done correctly, can lead your manufacturing firm towards a digital tomorrow. New tactics to understand the market and approach potential clients online can bring numerous challenges coupled with several interlinked factors. Different manufacturing firms have different challenges with several solutions; no one solution fits all. Help from a digital transformation expert can bring your firm to flourish online reducing the total cost, downtime, and inefficiency.

Conclusion

Two things that are essential for the Manufacturing Industry today are – considering the customer-centric approach and digital transformation of the operations and processes to lead a sustainable B2B business in a competitive market – The focus ought to be to overcome today’s challenges whilst keeping tomorrow’s success in mind.